Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🚀 Elevate Your Creativity with the CR-10 V3!

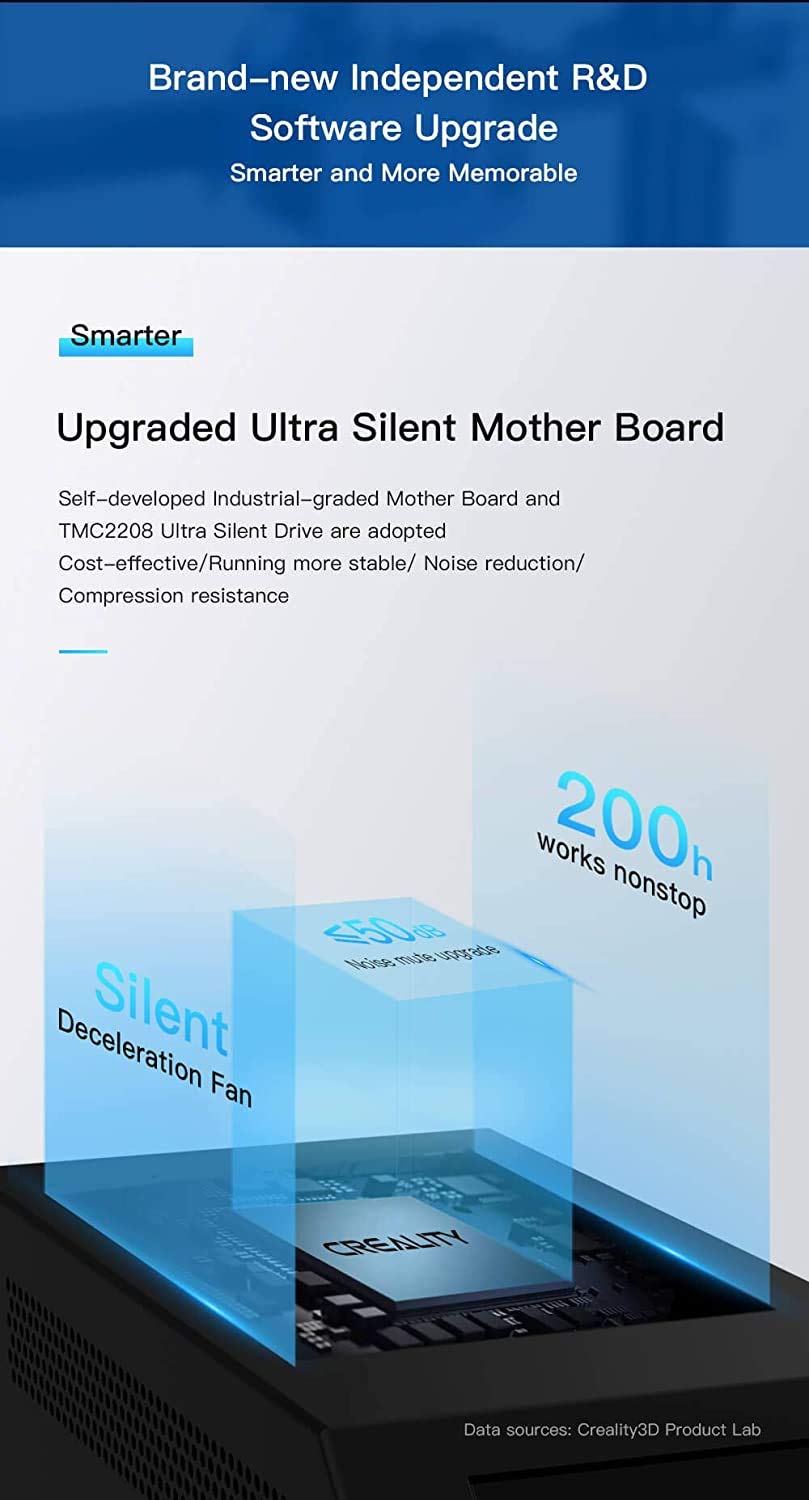

The Creality CR-10 V3 3D Printer is a cutting-edge machine featuring a Titan Direct Drive for enhanced filament control, dual part cooling fans for optimal heat dissipation, and a silent motherboard for a quieter printing experience. With a large build volume of 300x300x400mm and a robust all-metal frame, this printer is designed for precision and reliability, making it perfect for both hobbyists and professionals.

F**D

My 1st printer - Unbelievable machine. Ive included some setup info for noobs like me

I have a shop and regularly are in need of stupid things like a 5/16 to 3/8 fuel line adapter, so many times Im troubleshooting systems with different hose sizes and it drives me NUTS trying to muck around with inferior hacks - SO my first print was a 5/16 to 3/8 adapter! I went to tinkerbot and started messing around. My first design came out a little short BUT everything was perfect! I made a 2nd one that was longer without barbs and will refine it a bit. The print quality is more than excellent, I couldnt feel any roughness or see any distortion - the barbs came out SUPERBLY smooth and accurate!Shops want $4-$5 for ONE of these - NO MORE! I will now be printing out ALL my test equipment for the shop!Review:Bought this after spending WEEKS online pouring over reviews/specs and was eventually flipping between the ender5 pro and this unit but couldnt pass up the upgrades albeit for 200 more-Mine came partially assembled but its not half as complicated as some of the previous models ive seen - even for a beginner like me. The frame is super sturdy and helps moving it around too - very nice! Putting it together was not complicated (I rebuild engines for a living)..Pros:Everything is just so self explanatory for the most part - easy to assemble and follow instructions.Upgrades are very cool - as a 1st time owner I wasnt too keen to start modding and upgrading stuff, i just wanted the upgrades in place. Plus im not sure what would happen with warranty/upgrades. Anyway-The machine heats up quick and is super quiet (ctrl box fan is LOUD!)Hardly ANY fumes/odorsPieces just literally pop off the bed!Cant say enoughCons:Hmmm - none that come to mind..If you are on a tight budget Id probably opt for the ender 3/ ender 5 Pro but this unit comes with awesome upgrades.Super happy and cant WAIT to make this machine workNoob setup: Once you have the machine assembled (instructions are ok, the electrical connections are labeled which really helps and there are only 5 or 6) -FIRST:*** DONT FORGET TO SWITCH THE POWER UNIT TO 110v FOR THE US *** - it comes preset for 220v which I guess is safer.. if you accidentally set it to 110 and use 220 POOF so smart move by them.. 110 wont damage it on 220v setting.Machine Hardware Setup (Required)Next is bed leveling: READ THE INSTRUCTIONS.Step 1/3: Use the menu Prepare -> auto home (this just sets the nozzle at the corner of the bed).Step 2/3: Prepare -> disable stepper motors (this unlocks the motors so that you can move the bed and printer head by hand to set the bed height)Step 3/3: Now here is where you do the bed leveling - its easy, just be careful. Use a printer size sheet of paper, lay it on the bed and get it under the nozzle- now turning the large plastic wheel will make the bed raise and lower slowly.. adjust so there is medium drag on the paper, not super light, and not too hard.Repeat step 3 over and over and over starting with the 4 corners, each time you adjust one corner the rest will go out - keep going till they are all good. My first print wouldnt stick to the bed cos I didnt do it well enough so redid the leveling paying attention to spots all over the bed - once I did that i was in business.Software:First understand how 3d printing works. You have a 3d model (eg: a potato). A 3d file is just a potato and there are hundreds of different programs, printers and settings (slicing) - for example you can print the SAME potato in 2mm OR 3mm slices, same potato - different "slicing" (or fries), so slicing is required before EACH print to suit the printer AND slice settings. Slicing also allows you to rectify issues, like slowing the first layer to make the model stick to the bed but thats another write up..SO the first thing you wanna do is download Cura and select the cr10 as your model - Cura is now matched to the cr10 series and knows how to process 3d files into slices that match your machine.So now everytime you download a 3d file (stl from thingiverse for example) or MAKE a new model (online at tinkerbot), you will load tjhe stl file into cura, slice it (one click really), export/save to sd card- and now your potato is actually a bunch of fries ready to be printed.When you load the sd card into the printer you will see it in the list under "print" settings - click on it, bed will preheat and after 2-4 minutes the printing will start!I HIGHLY recommend a bed level test print at first.. there is a great one that takes under 5 minutes and prints large squares across the bed - this will confirm your settings are good. Waiting for a 20 minute print to fail is not right so dont use the animal samples for this.After you get good at this you will discover and explore more info/options/programs -

C**N

Easy to assemble and use, even for a dummy like me

I’ll start by saying this was my first 3D printer and that I’m in no way mechanically inclined. I’ve actually struggled putting together IKEA furniture before. So when I read about how complicated it could be to assemble these machines, I was pretty nervous. I shouldn’t have been. All told, I probably spent about 2-3 hours lazily putting it together in between work calls and other projects. The instruction manual wasn’t the clearest thing I’ve ever read, but a couple YouTube videos and little trial and error later and I was printing calibration tests without issue. Even the bed leveling was relatively easy — by my third print I had it dialed in and printing without issue.Don’t get me wrong — it wasn’t perfect out of the box. The bed, for example, was somewhat warped. But I had ordered a well-reviewed glass bed as well and it was perfect after the swap. The recommended heat settings were also a little off. But after bumping the bed heat up to 60, I haven’t had a single problem with adhesion. I haven’t even needed glue or hairspray. Everything just sticks perfectly, then pops off after a few minutes of cooling.I still have a ton to learn and it’s clearly more art than science, but I’ve been incredibly impressed so far. For the price, this is a perfect entry level machine that’s big enough to print pretty much anything I could ever want.

B**R

Good printer, but be ready to work on it.

My ancient 3d printer died, so I took advantage of Prime Day sales to get this printer.Out of the box, it came together easily. Definitely watch a video or two to make sure you're ready. I went to power it up and ... no power! I checked the breaker box, verified the outlook worked, and scratched my head. Until I saw the little red switch on the side of the control box. Sure enough, it was set to 230 amps instead of 115. Switched that to the correct US setting, and it started right up.Next issue is the well known failure of the filament runout sensor. I tried to run a roll of 1.75mm through it and I couldn't even get it to threat through. So I followed the tips online, snipped off a piece of filament and stuck it in the hole. It is enough to make the sensor register filament, and I just manually make sure I don't run out. Some day I'll print the "fix", or drill out the hole so filament can freely go through the sensor, but I really don't need it personally.On the good side, I bought the BLTouch with the printer, and it easily mounted and works perfectly. Prints are pretty solid, the carbonite bed cleans easily and prints stick fairly well. I've had a few problems with some acute angled prints pull up if you're not careful.After a few days of printing, it started to make this horrific screeching noise when starting a print. This noise lasted for 5-10 layers, then dropped off. It consistently did this, so after 5 or 6 prints I bit the bullet and took apart the printhead. I suspected one of the two bearings in the extruder was the issue, and sure enough one of them literally crumbled in my hand. Amazon to the rescue. I contacted the seller, and they sent me a complete new extruder assembly. However, it took on the order of 10 days to get through the back-and-forth emails and the shipping from China. Again, Amazon to the rescue! I ordered a bag o' bearings immediately when it failed, and they were here the next day. So I was back printing while waiting for Comgrow to verify my address, and get the package sent. Nice that I have spare parts now!The only other issue is that the fans in the control box a LOUD! These are not the cooling fans on the printer itself, just the ones in the control box. It's really annoying, and is another common fix-it issue. When I have the time, I'll pick up some silent fans and replace the loud ones.Bottom line - this is a solid printer that works well.PROSThe direct drive extruder is great, the bed is excellent for PLA (all I've printed so far), it levels easily, and the tight BLTouch integration makes it even better.the Amazon seller is responsive, although half a world away makes communication slowCONSFilament Runout Sensor is too tight and in my case wouldn't even let filament pass throughControl box fans are LOUDQuality control needs help - shipping with dry, dead bearings is inexcusable, and the control box should be set to US power when shipping to the USBonus - I would HIGHLY suggest getting on Nic's Creality 3D Printer Firmware Facebook group. Nic rewrote the firmware and it is a LOT better than Creality's downloads.

Trustpilot

1 week ago

2 weeks ago