Full description not available

O**R

Works and easy to use!

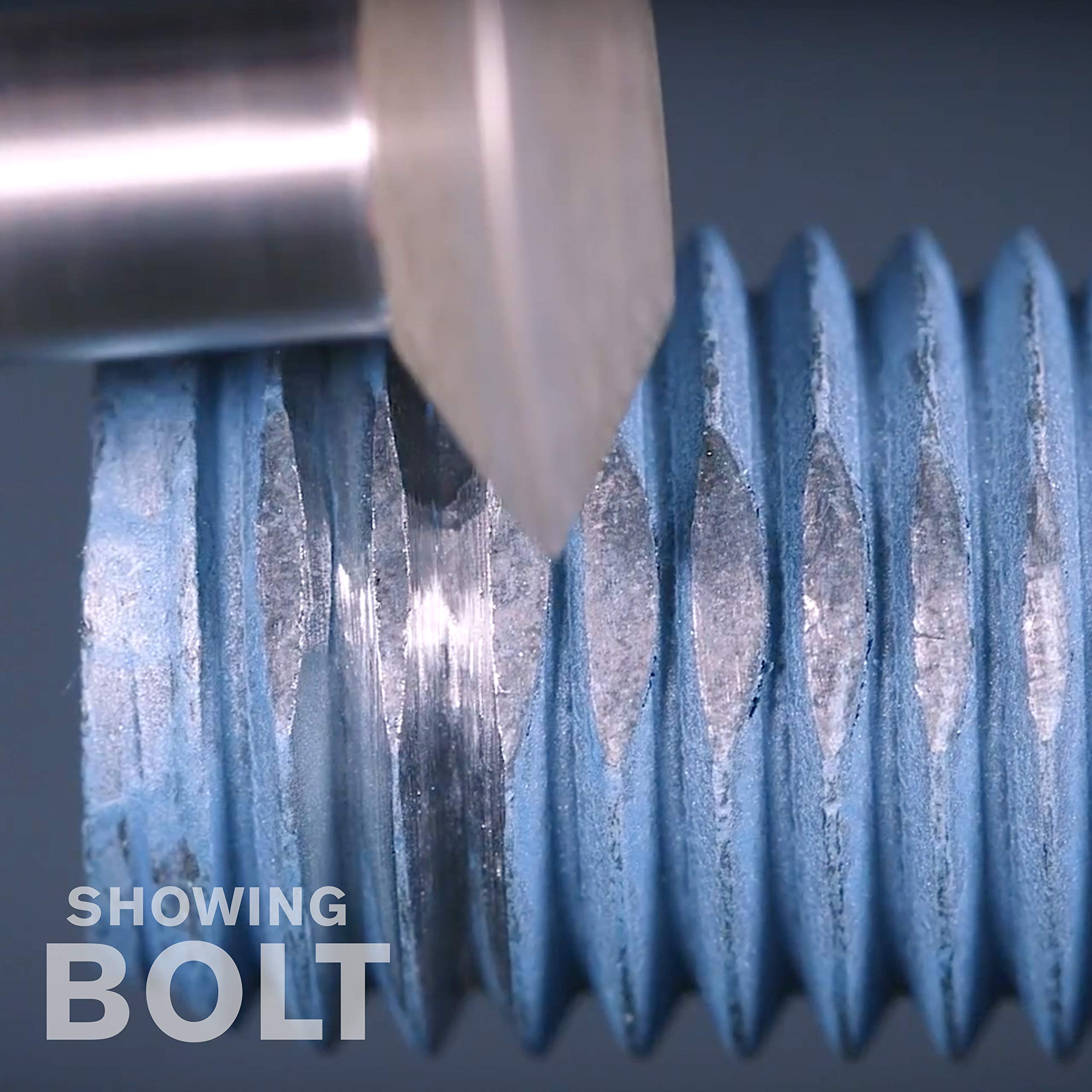

I removed the grab rails off my sailboat to remove layers of varnish and then apply teak oil before re-installing. The nature of these grab rails are that they have 7 stud bolts on each of the two rails and they firmly attach the rails to the top of the cabin - The studs pass thru drilled holes in the Fiberglas and then washer, lock washer and nut hold the rails firmly on top of the cabin. The bolt head end of the stud is not visible - It is inside the top of the rail and wood plugs contoured to the top of the rail hide the bolt heads. These studs should never have to be removed from inside the rail and to do is a chore since the plug would have to be drilled out and a new one installed and contouredmto the rail. Initially, when I removed the nuts from the studs inside the cabin, one of the nuts was had to unthread from the stud and the stud started to rotate within the rail. So, I had to use pliers to hold the stud tight and another set of pliers to unthread the nut. When it was time to re-install the nut, I could not thread it onto the stud. My pliers had ruined the lower threads.I was considering using a diamond cutoff wheel on my Drexel to remove the lower threads but that would leave few threads available to re-install the nut and besides The nut was had to unthread it initially, so I would still be face with that problem as well.I then discovered the EZThread 382 searching the web and Amazon for solutions either by buying a different type of fastener to clamp to the existing threads but then I came across this tool to repair existing threads.The 382 mini-grinder tool was easy to use. It just about 1-2 minutes of use, I was able to get the nut back on. But other threads made it hard to completely re-install the washers and nut, so I tweaked addl threads and kept testing how easy it was to completely install the nut. After only another few minutes of tweaking the threads, the nut washers and nut were able to be re-installed easily. Since I was now able to rethread the nut all the way up to the inside cabin top, the friction fit at the bolt head kept the stud from rotating within the rail and I was able to torque the nut fine. So, this tool not only repaired the initial threads to get the nut on but tweaking the rest of the threads enabled me to utilize the stud, get a tight fit, without having to replace the stud which would have been a much longer repair and would have required labor to replace and contour a new plug on the outside of the rail.This is a great tool ! I am telling all my friends about it !

J**E

Where has this been all my life?

I'm a mechanic. Damaged threads are just part of the job sometimes. The case that brought me in contact with this tool was a spindle on the rear end of a Dana 80 truck axle. It would have required a $200 3" threading die. I decided to try this tool. I took something that looked beyond repair and transformed it to the point where the large lock nut spun on by hand.It takes some skill. It's not a toilet plunger. You need to have a steady hand and a good Dremel tool but the payoff is quite impressive. It's a tool anyone who works on anything threaded should have. It saved my butt and a buttload of money as well.

W**S

IT WORKS!

It's very rare these days that things actually work, and this thing worked. Saved me $985!. We have a firetruck and one of the hose reels threads had corroded to the point of no return. The replacement cost was extremely expensive as the thread is attached to one piece and can not be replaced. I gave this thing a try as a hail-mary and it actually worked. Half of the threads were on the backside that I couldn't see so I just followed the front threads and prayed that i wouldn't jump over a thread. Followed it all the way back around and kept going. Used a little Brakleen to clean off the grit and the coupler fit right on first time around. I still cant believe it.

M**N

Five Keys to Success With This Little Gem of a Tool!

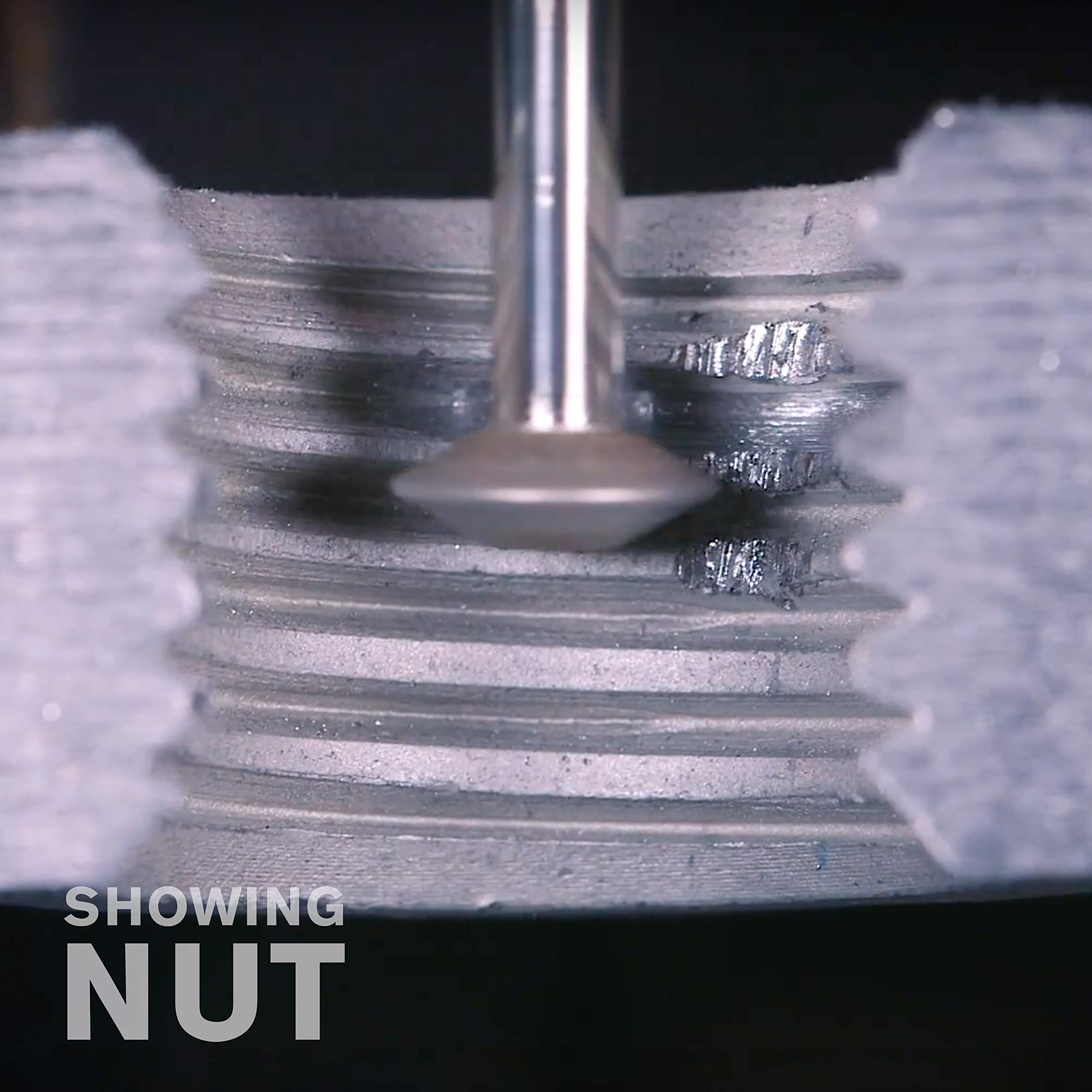

Keys to success with this little gem of a tool.FIrst of all, I am not at paid representative of this tool! I love tools that perform as advertised! And I love quality tools. This tool saved me hundreds of dollars and countless hours of work. My outboard motor thermostat housing is a 1-1/2" aluminum threaded bore and has a "composite" cover. The threads are 16 TPI (threads per inch) when I went to unscrew the "composite" cover to gain access to the thermostat the whole threaded piece snapped away leaving all the threaded piece inside the housing bore! So I had to chip away the threaded section of the cover (plastic) from the aluminum housing with a diamond point chisel (another gem of a tool.) While I was very careful not to damage the aluminum threads while breaking the plastic threads out I managed to nick a couple of places but not too bad. I looked for a 16 TPI internal thread file online and boy are they expensive. And they are limited in reach on an internal thread. I had never heard of this Rotary Thread File tool before. Being a retired machinist/millwright I often could of used this tool many times. Anyway I came upon the Rotary thread file site. And ordered the 754, 4" long little gem. I already had my comp. hose and 30,00 RPM die grinder ready before the tool arrived 3 days later, but thought this was overkill, and if the threads weren't perfect I would ruin my new composite cover threads? This wasn't a 30,000 RPM moment. So, I placed this magic tool it into the not easily accessible threaded bore and slowly began moving it into the damaged area and spun it with my right hand fingertips while supporting it with my left hand I could feel it cutting. I used it dry with no cutting fluids so I could blow the shavings and deeply embedded corrosion out from the bore. (thank you saltwater) After about 10 minutes I was able to hand thread my new composite cover in with two fingers. I Assembled the thermostat housing with new gaskets and "O" ring, test ran engine with no leaks. What a cool little tool, I used it on all the threads to clean the deeply imbedded corrosion in the bottom of the threads. All by hand. It is also a good thread chaser and cleaner. This is an ingenious tool! All threads are the same angle, (60 degrees) fine, (SAE) coarse, National, Metric, Pipe, etc., this little tool is the perfect angle of the thread, thats why it works! It even works on any different amounts of thread per inch, (Pitch) because they are still 60 degrees. It isn't designed for acme threads (Drilling rig and valve stems) and other mophodite or speciality threads. But at your request I believe you can special order the correct one for those. So it will work on any normal thread, especially on all the threads my retired a#* will come across. This will be a hot item in everyone's toolbox. Don't bother to, watch the YouTubers demonstrating this tool. (They were traveling the wrong way, attacked bad threads from the top) etc. etc. (it does make for a "How Not to Grind Threads With a Rotary Tool" video). You'll want to reach through the screen and grab it from their hands and show them the right way to use this tool, with finesse and much better results. After watching these guys work and mangle some already mangled threads (I wouldn't let them check the air in my tires!) But guess what when they finished with their "hope for the best moment", they were successful, it wasn't pretty but it does show that you don't need any special skills to have success with this little tool! I never used this tool in a Rotary tool such as a die grinder. (Ididn't need too!) But I have used all types of grinders including high speed air grinders many, many, times over the period of a 42 year career of Pipe fitter/welder and Machinist/Millwright. From that experience I think I can Suggest 5 Key tips to help you use this tool with confidence for the squemish or nervous type working with power tools. (1) As with all rotating tools and grinders they need to be used in a certain rotational direction in relation to your direction of travel to avoid kick-back. So attack the bad thread area from "under" the front part of thread with the bottom of stone rotating up toward that area. You should learn the rotation of the tool you are using before starting. For this example let's figure Clockwise and counterclockwise is with the tool in your hand looking from the rear of the tool to the disc or stone. Cut with the tool traveling to the left if your tool rotates clockwise. Cut with the tool traveling to the right if your tool rotates counterclockwise. This keeps the tool from climbing up from the bottom of the threads and skimming on the top of the thread uncontrollably. (2) Prop your tool hand. Find a way to support your tool to give you better control. Use both hands. (3) Make a dry run with the tool disconnected from power. This will give you the feel of proper placement of the tool, especially if you are repairing fine threads. 4) Hold the tool perpendicular to the threads at all times. If you have to stop to reposition, than do so, but get another spot to prop. Remember you can't travel very far without loosing your 90 degree perpendicular hold. (5) Finally don't work your stone. Let the stone do the work. Move the stone very slowly with very very light pressure and try to approach the bad thread with the rotating stone at the bottom of the groove. You may not be able to attack it from the top of the thread and maintain control. You'll have better control if you use the bottom of the groove as a guide working into the damaged area, don't rush and don't try to make the repair in one pass. There is a certain amount of finesse needed here! Taking your time yields better results. If you use these steps you could probably use it by feel alone if it gets hard to see at times. If this happens slow down and let the tool tell you if your "in the groove". Good Luck!Hopefully these steps dont scare you. These tools are simple to use! Granny could use them. These steps are to make you and some of the "YouTubers" more informed with basic rotating rools use and to teach you to think every job out ahead of time. Sorry I know these steps were similar to a safety meeting and meant for someone with little to no experience. But if they helped you, your welcome. If you already knew these steps your welcome too. It doesn't hurt to refresh!! LOL . Good Luck! & Work safe!

T**7

Works surprisingly well !!

Although I was shocked by how small it is - it saved a damaged 3/4" threaded rod I had already welded to a bracket. I used a Dremel and magnification and was able within a few minutes to get the nut to travel the full length of the rod. ONE LIMITATION is this works best where you can get the tool perpendicular to the threads being repaired. Even using a Dremel extension I had to work at a slight angle 6" from the end of the rod which wasn't a problem due to the large threads I was fixing but it could be an issue on finer threads.